A recurring inquiry pertains to the equilibrium of CHRA (Center Housing Rotating Assembly) units and the variations in balance graphs among different Vibration Sorting Rig (VSR) machines. This issue often raises concerns among our clientele. When they receive a balanced CHRA from SHOUYUAN and attempt to verify its balance using their own equipment, discrepancies often arise between their machine’s results and the graph provided with the CHRA. Consequently, the CHRA might appear unbalanced on their apparatus, rendering it unacceptable for use.

The process of balancing high-speed CHRA units on a VSR machine is notably intricate compared to low-speed rotor balancing. Numerous factors significantly influence the residual imbalance of the assembly at high speeds. Notably, when a CHRA reaches its operational speed on a VSR machine, the machine’s frame and mechanism resonate, resulting in a specific vibration reading. Crucially, during the manufacture of a VSR machine, identifying the machine’s exact resonance and utilizing software to nullify this vibration profile for each CHRA’s operational testing is a critical process. Consequently, only the CHRA’s vibration, displayed on the screen, remains.

In essence, manufacturers encounter difficulties due to slight variations in machine vibration caused by numerous uncontrollable factors across different machines. Recognizing this variability elucidates the differences observed between machines.

Two primary variations merit attention:

Adapter Differences: Varying adapter designs between manufacturers and even within adapters of the same turbo part number lead to differing vibrations during operational testing. This divergence stems from variations in properties such as casting wall thickness, plate thicknesses, and material properties among adapters, influencing their vibration levels.

Clamping Force: Variances in clamping force applied to secure the CHRA into the housing affect the transfer of vibrations from the CHRA to the machine. These differences arise due to various factors, including machining variations in taper components of adapters, distinct clamping forces applied by operators, and diverse taper designs among machine manufacturers.

Consequently, achieving identical balancing graphs for the same CHRA across different machines becomes arduous due to these inherent discrepancies.

It’s noteworthy that while variations between machines exist, they should generally align since the machines are engineered to yield similar outcomes.

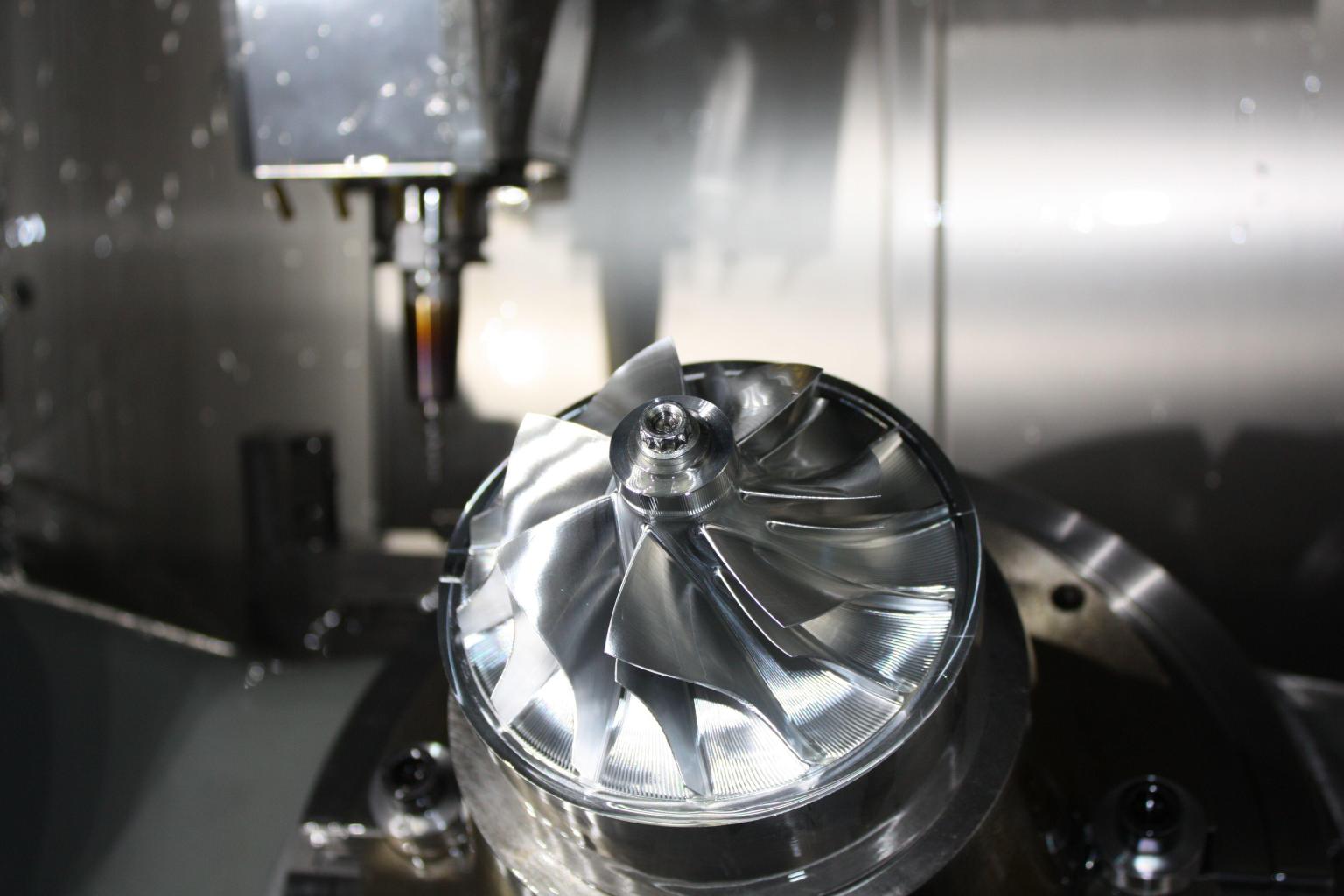

Detecting balancing failures is relatively straightforward during failure analyses, as imbalance typically manifests as a taper shape in the journal bearings. At SHOUYUAN, with over two decades of expertise in manufacturing top-quality turbochargers and turbo parts, including cartridges, turbine wheels, compressor wheels, and repair kits, we assure our customers of versatile products suitable for diverse vehicles. Committed to delivering superior products and exceptional service, we maintain stringent quality control, ensuring our customers can get satisfactory products they want.

Post time: Dec-06-2023